PrecisionAluminum & Zinc Die CastingSolutions from Vietnam

High-pressure, gravity, and zinc alloy casting backed by expert engineering and a network of 1,000+ factories.

Full Technical Support

From DFM to tolerance control

Certified Factories

ISO-certified, export-ready manufacturing

Precision & Volume

Low to high volume, tight tolerances

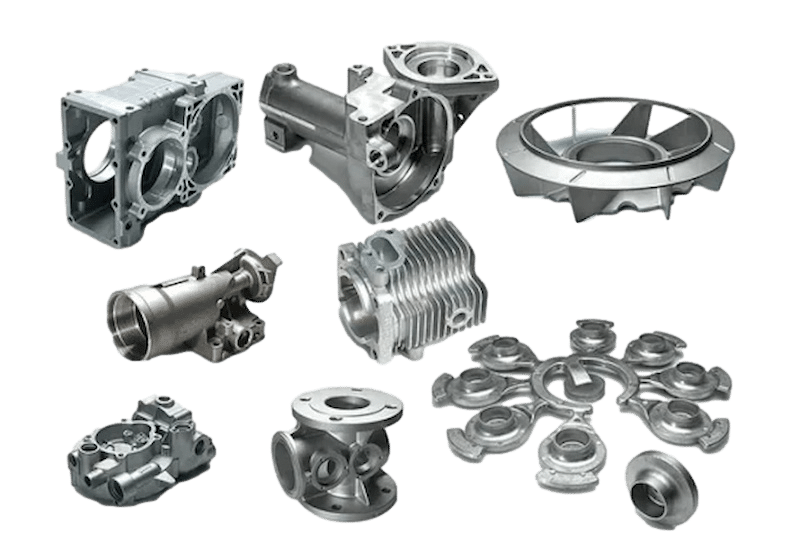

Our Capabilities

VDC Die Casting Capabilities

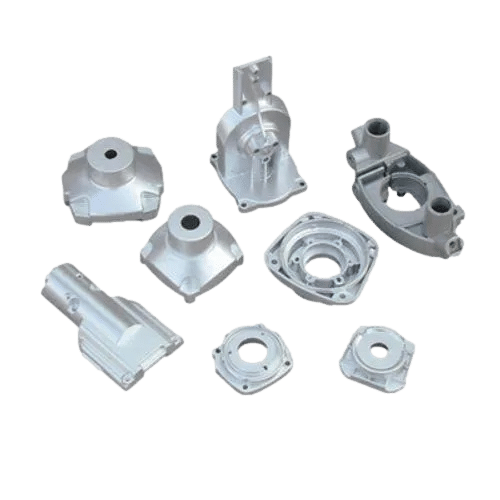

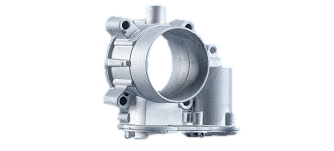

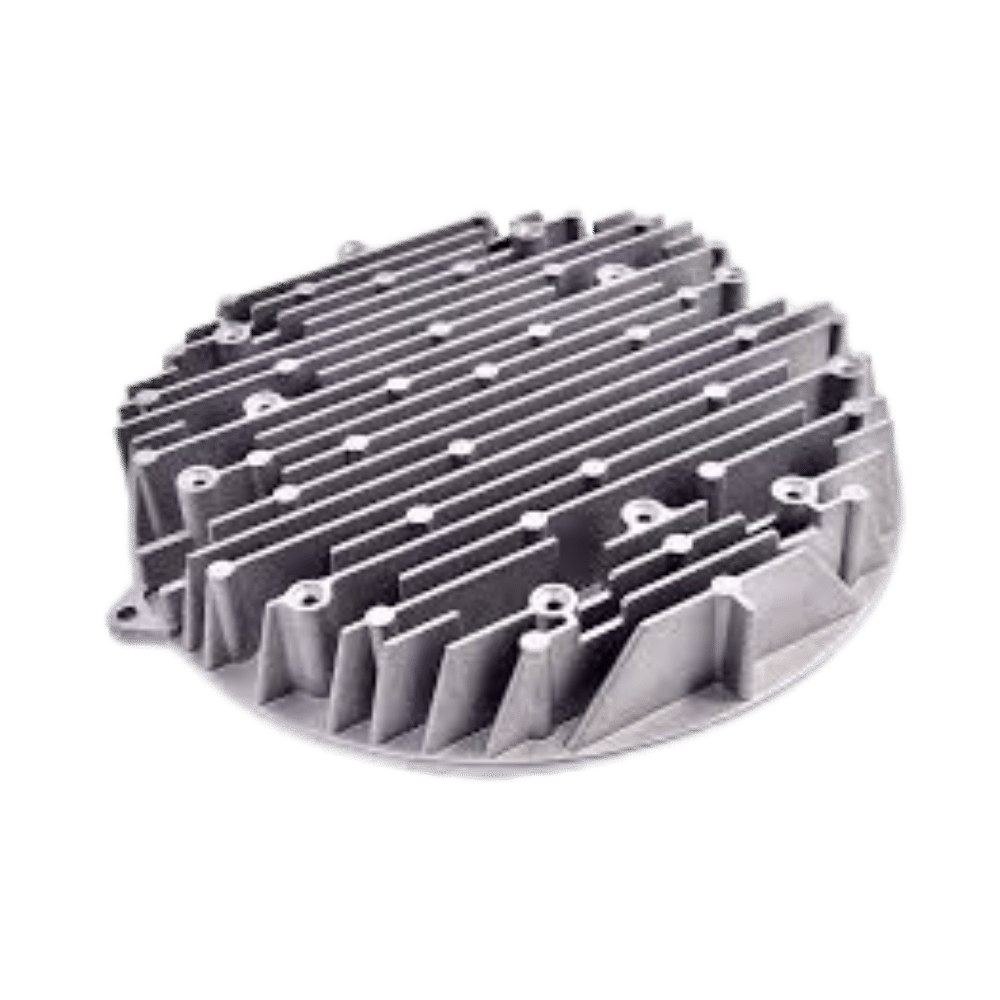

High Pressure Die Casting (HPDC)

Best for: High-volume production of complex aluminum or zinc parts requiring tight tolerances and smooth surfaces.

Description: HPDC is our most requested method due to its speed, repeatability, and compatibility with intricate part designs. Molten metal is injected into a hardened steel mold at high pressure (up to 2,000 bar), producing near-net shape components with minimal post-processing. It’s ideal for automotive housings, telecom enclosures, and consumer electronics.

Materials Supported: ADC12, A380, Zamak 3, Zamak 5

Applications: Engine blocks, gear housings, heat sinks, lighting housings

Gravity Die Casting

Best for: Medium-run parts with thicker walls and stronger mechanical integrity.

Description:

This method relies on gravity to fill the die cavity — without applying external pressure. While slower than HPDC, it enables the use of denser alloys and delivers stronger, more ductile components with lower porosity. Gravity casting is a preferred choice for components requiring excellent weldability and fatigue resistance.

Materials Supported: A356, A319 aluminum alloys

Applications: Pump housings, cylinder heads, pipe fittings, lighting brackets

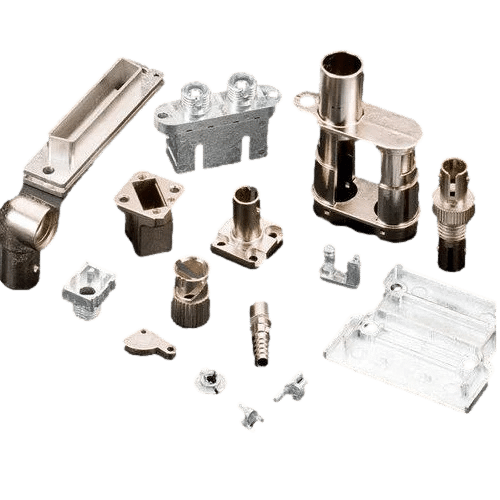

Zinc Die Casting

Best for: Small-to-medium parts requiring exceptional detail, thin walls, and high surface finish.

Description:

Zinc die casting offers outstanding dimensional stability, corrosion resistance, and cost-effectiveness — especially for consumer products, locks, connectors, and electronic housings. With a low melting point, zinc alloys reduce mold wear, making them excellent for long-run, high-precision parts.

Materials Supported: Zamak 3, Zamak 5

Applications: Door handles, gear levers, connector housings, brackets

Magnesium Die Casting

Best for: Ultra-lightweight components in automotive and electronics.

Description: As the lightest structural metal available, magnesium is increasingly used in EVs, drones, laptops, and mobile devices. Magnesium die casting enables the production of rigid, thin-wall parts that combine strength with significant weight savings. Our facilities support the safe handling and casting of AZ91D and AM60 magnesium alloys with strict safety protocols and expertise.

Materials Supported: AZ91D, AM60B

Applications: Steering wheel frames, seat bases, laptop shells, drone frames

Our Capabilities

Materials We Work With

Aluminum Alloys

A380, ADC12, ADC10, A383

Zinc Alloys

Zamak 3, Zamak 5

Magnesium Alloys

AZ91D, AM60B

Our Capabilities

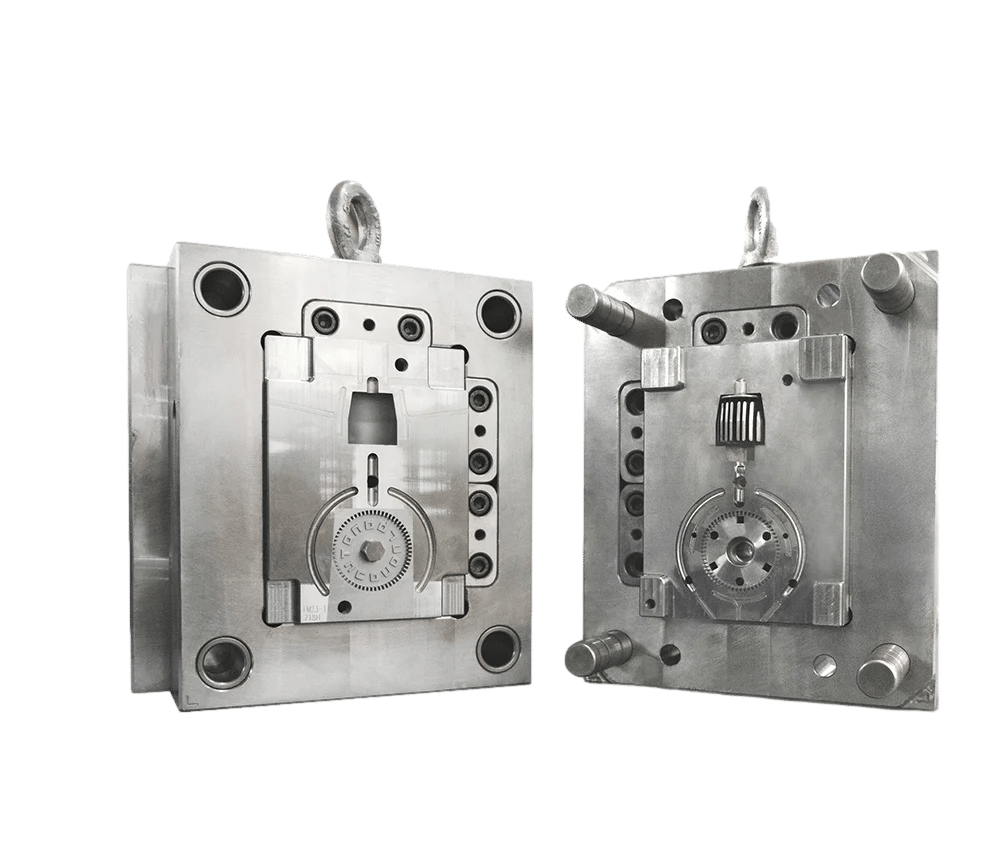

Tooling & Mold Support

-

Custom Mold Design for Die Casting

Our engineers design precision molds tailored to your specific part geometry, alloy, and production needs. Using advanced CAD/CAM tools, we ensure optimized flow, minimal porosity, and reduced cycle times from the start.

-

Mold Flow & Thermal Simulation

We use digital mold flow analysis and thermal simulations to predict how molten metal fills the cavity. This reduces the risk of defects, shortens prototyping time, and ensures superior casting performance.

-

Lifecycle Optimization & Tool Maintenance

Phasellus viverra nulla ut metus varius laoreet. Quisque rutrum aenean imperdiet etiam ultricies nisi vel augue ullamcorper.

-

Alloy Compatibility Engineering

Our team evaluates the metallurgical properties of aluminum, zinc, and magnesium alloys to match them with the most efficient die casting parameters for your application, ensuring structural integrity and surface finish.

-

Post-Casting Machining Integration

We provide seamless integration with CNC machining services for post-casting processes like milling, drilling, and threading—ensuring parts meet tight tolerances and functional specs.

-

Rapid Prototyping & Pilot Runs

Before full production, we offer rapid prototyping and small-batch pilot runs to test and refine mold performance—reducing risk and improving product development speed.

Our Capabilities

Industries We Serve

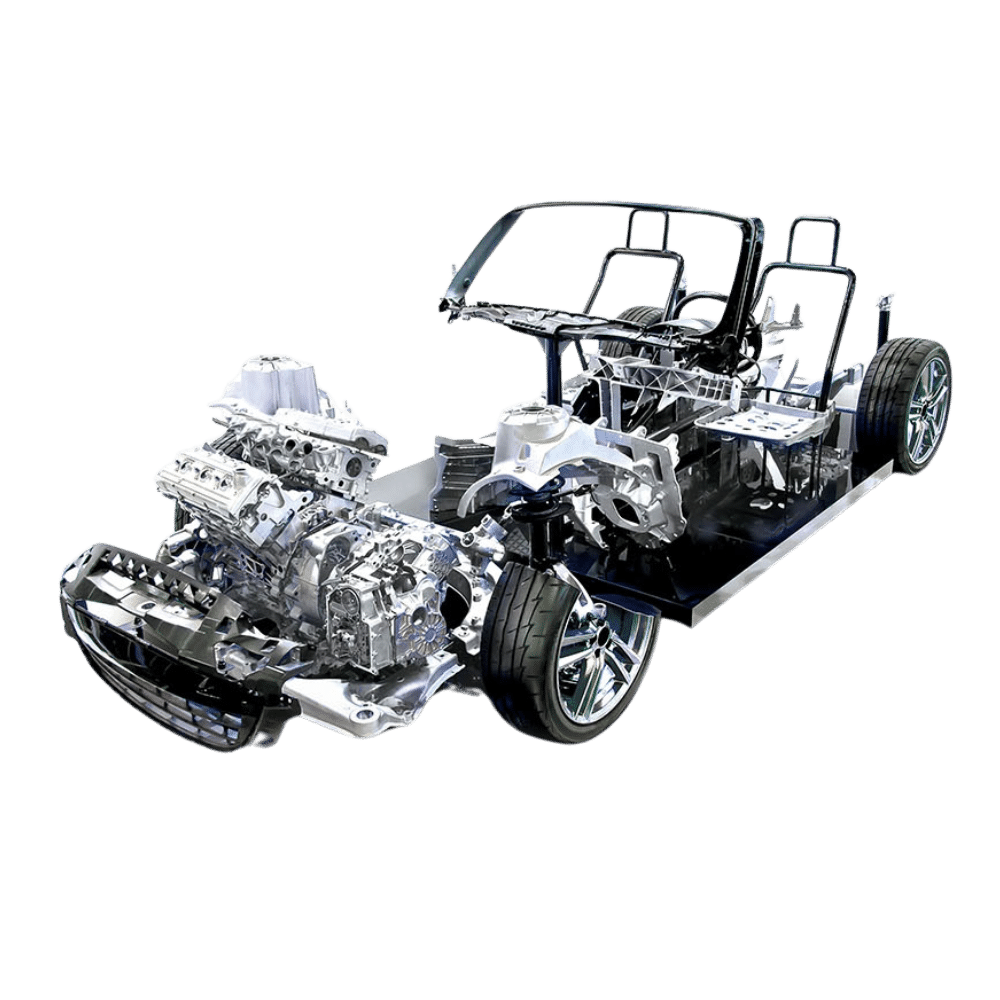

Automotive Die Castings

Engine blocks and covers, transmission housings, gearbox casings, steering wheel frames, shock absorber parts, brackets and mounts, oil pump housings, turbocharger components, EV battery enclosures, and motor controller casings.

Consumer Electronics

Smartphone and tablet housings, laptop and desktop casings, heatsinks for CPUs and GPUs, camera frames and brackets, charger enclosures, smart speaker housings, and cooling fins or modules.

Lighting & Appliances

LED lamp heat sinks, lighting fixture housings, microwave brackets, refrigerator compressor casings, washing machine frames, ceiling fan motor bodies, and oven handles and knobs.

Telecom & Defense

5G antenna enclosures, RF shielding enclosures, satellite dish mounts, military-grade casings, communication box housings, radar component shells.